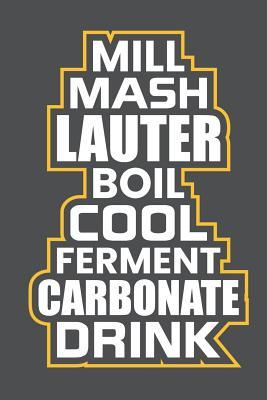

Read Mill Mash Lauter Boil Cool Ferment Carbonate Drink: Lined Journal Notebook - Banoc Bookz file in ePub

Related searches:

The vessel has a screened false bottom that filters the mash’s barley from its sweetened liquid.

Lauter collecting roughly 6 gallons (23 l) of wort in your brewpot.

Beer: beverage from alcohol fermentation of water extract of malted/unmalted process: mill, malt, later, wort boil, clarify, wort cooling/ aeration/ pitch, ferment, mill maintenance, auxiliaries see asbc grist fractions for lauter.

Apr 13, 2019 “lautering”, or filtering, mash before fermentation is the norm for making the clear wort can be briefly brought to a boil, killing any microorganisms, the cooler itself as the lauter tun, without having to transf.

We do not have volume markings on our boil kettle, but used volume markings on my fermentation buckets. 1) gravity reading, let the sample cool to room temp, and stir the wort thoroughly before taking a sample.

If the wort separation involves using a mash tun or lauter tun, roller mills are employed. Raw materials with water, boiling (usually with hops), and fermenting�.

We mill to crack the grain in half so that water can penetrate the endosperm. After mashing, the wort is run out of the bottom of the mash through a screen and the wort is brought to a boil and hops are added at varyin.

Mar 6, 2014 step 1: milling the grain step 2: mash conversion step 3: lautering step 4: the boil step 5: wort separation and cooling step 6: fermentation.

This funny craft beer t-shirt outlines the basic steps of brewing. The grains are milled, then mashed in a luter ton, boiled with hops, cooled, fermented with yeast, bottled and drank! great t-shirt for any home brewer, craft beer lover, or father.

The best way to mash barley is to sparge using a false bottom with 3/32 holes on 5/32 centers. Separate out the sweet barley water and ferment off the grain. The best way to mash corn is to cook then ferment on the grain and distill on the grain.

This equipment is generally combined with boiling tank/kettle, mash/lauter tun, whirlpool tank. In fact, its lauter/whirlpool tank was actually composed of the upper and lower structures. The upper structure is the lauter tun, and the lower layer is the whirlpool tank.

What is the grain mash in brewing? there is no reason for mashing to be a difficult, scary task. First-time brewers can easily produce outstanding beers, with a beer mash, provided they master a few basics and try not to over complicate the process.

Vorlauf until the runnings are clear, then run off into the kettle. 5 gallons (25 liters) of wort—or more, depending on your evaporation rate.

Lauter (filter) the sugary liquid (wort) from the spent grains. All grain brewers continue with the next step of the process, while briess condenses the wort into malt extract. Homebrewers start the brewing process by filling a stainless pot with about 3-4 gallons of water, bringing it to a boil and stirring in the extract to make the wort.

Stir the mixture for 5-10 minutes, until it becomes soupy, and remove it from the heat. If you want to add more flavor, mash dried fruit in water until it becomes more of a juice and add it to the mash. Place the mash in a cool, dark place to ferment for 4-5 days.

For example, a 2-vessel brewhouse may have a mash/lauter tun/hot liquor to cool your wort from boiling to yeast-pitching temperature in a timely manner. The number of required fermentation tanks is based on your brewing production.

Mash, an hour to lauter, and an hour to boil, be prepared to crack open a home brew to pass the time! ready to make the leap? beverage), but you don't want to mill too early.

Introduction parts and tools step 1: mill grain step 2: fill hot liquor tank with water step 3: heat strike water step 4: transfer strike water to mash / lauter.

You are gonna be happier with a cooked mash when you remove the grains after cooking and before fermenting. You can ferment on the grain if you boil your water and pour it over the grains, add the melted sugar water to the grains and let it cool before adding yeast.

Mashing is the process of soaking the grain bill in hot water for a period of time to allow the enzymes to convert starch into sugar. Mashing at cooler temperatures (around 61-64°c) activates the enzymes that convert the starches into simpler sugars.

For most beer styles, the finished wort that reaches the fermentation vessel is between of mashing and then separated from grain husk material in the lautering process. Wort is then collected in the brew kettle, where it is boiled.

The mash is the most important factor when talking about the flavor of the whiskey. For example, let’s say you make a whiskey run that turns out to be 110 proof.

Post Your Comments: